Blood tubes play a vital role in healthcare by safely collecting and storing patient samples. You rely on their quality to ensure accurate results. Understanding how manufacturers create these tubes helps you appreciate the strict standards that guide each step.

Testing the materials used in production keeps samples safe and free from interference.

Integrity checks confirm each tube can securely hold blood.

Sterility testing prevents contamination, which protects test accuracy.

This knowledge supports your confidence in reliable medical testing.

Blood tubes serve as essential tools in clinical laboratories. You use them to collect, transport, and store blood samples for a wide range of diagnostic tests. Each tube is designed to preserve the integrity of the sample and support accurate laboratory analysis. When you select the right blood collection tubes, you help ensure that specimens remain uncontaminated and suitable for testing.

You rely on blood collection tubes every time you draw blood for analysis. These tubes come in different colors and contain specific additives. Each type supports a unique set of tests and preserves samples in a way that matches the requirements of those tests. The table below outlines the most common types of blood collection tubes, their uses, and the additives they contain:

| Tube Color | Common Uses | Additives |

|---|---|---|

| Red-Top | Blood typing, serum collection, certain immunology tests | None |

| Blue-Top | Coagulation studies, PT, aPTT, and INR tests | Sodium citrate (anticoagulant) |

| Green-Top | Plasma collection, blood gas analysis, cholesterol tests | Heparin (anticoagulant) |

| Yellow-Top | Blood cultures, DNA testing, tissue typing | ACD or SPS |

| Purple (Lavender)-Top | Complete blood count (CBC), blood banking, hematology tests | EDTA (anticoagulant) |

| Grey-Top | Glucose testing, lactic acid testing | Sodium fluoride (glucose preservative) |

| Black-Top | ESR (Erythrocyte Sedimentation Rate) | Sodium citrate (anticoagulant) |

| Pink-Top | Blood typing, crossmatching for blood transfusions | EDTA (anticoagulant) |

When you choose the correct tube, you help maintain the stability of the sample. This choice prevents unwanted chemical reactions and supports the accuracy of test results.

Note: The color-coded system makes it easy for you to identify the right tube for each test, reducing the risk of pre-analytical errors.

Blood collection tubes impact the reliability of laboratory results in several ways:

You protect specimen integrity by preventing contamination and ensuring proper handling.

You avoid pre-analytical errors by selecting tubes with the right additives, which prevents components from leaching into samples.

You support timely and reliable test results by matching the tube type to the specific test requirements.

You play a key role in the diagnostic process by understanding how blood collection tubes function. Your attention to detail ensures that samples reach the laboratory in optimal condition. This careful approach helps laboratories deliver precise and trustworthy results for every patient.

Blood collection tubes contain several essential components that help you collect, preserve, and process blood samples for laboratory testing. Each part of the tube serves a specific function, ensuring that you obtain accurate results for a wide range of assays. When you use plastic blood collection tubes, you benefit from their durability and safety, which are critical in busy clinical environments.

The main components of blood collection tubes include the tube body, the closure or cap, and the internal additives. The tube body, often made from medical-grade plastic, provides a sterile environment for the blood sample. The closure seals the tube, maintaining sterility and preventing leaks. Additives inside the tube play a crucial role in preparing the sample for different types of assays, especially those involving coagulation.

The table below outlines common types of plastic blood collection tubes, their additives, and their functions:

| Tube Type | Additive/Component | Function |

|---|---|---|

| Serum Separator Tube (SST) | Gel separator | Separates serum from blood cells after centrifugation for various assays. |

| EDTA Tube | Ethylenediaminetetraacetic acid | Binds calcium to prevent clotting; used for hematology assays. |

| Heparin Tube | Heparin | Prevents clotting; used for plasma assays like coagulation studies. |

| Sodium Citrate Tube | Sodium citrate | Acts as an anticoagulant; used for coagulation assays. |

| Fluoride Tube | Fluoride and anticoagulant | Prevents glycolysis; used for glucose assays. |

| Blood Culture Bottle | N/A | Collects specimens for microbiological culture to identify infections. |

You rely on specific additives in blood collection tubes to maintain the integrity of your samples. These additives help you prepare samples for specialized assays, including coagulation assays, which require precise control over the blood’s clotting process. The most common additives and their purposes include:

Anticoagulants such as sodium citrate and heparin prevent clotting and maintain sample stability. You use sodium citrate tubes for coagulation assays because citrate binds calcium and stops the clotting cascade.

Stabilizing agents like EDTA and fluoride oxalate preserve cell integrity by inhibiting enzyme activity. These agents help you perform accurate hematology and glucose assays.

Drawing aids, including gel separators, make it easier for you to separate serum or plasma from blood cells after centrifugation. This step is vital for many assays, especially those that require clear separation for analysis.

Preservatives reduce bacterial growth and protect your samples from contamination, ensuring reliable results.

When you select the right plastic blood collection tubes, you support the accuracy of coagulation assays and other laboratory tests. You ensure that the sample’s properties remain unchanged from collection to analysis. By understanding the function of each additive, you can match the tube to the specific requirements of your assays, especially when performing coagulation studies that depend on precise citrate concentrations.

Tip: Always check the tube label and color code before collecting blood for coagulation assays. Using the correct citrate tube ensures valid results and prevents errors in your laboratory workflow.

You begin the step-by-step guide to manufacturing vacuum blood collection tubes by selecting high-purity materials. The quality of your samples depends on this first step. You choose between plastic and glass, but most modern vacuum blood collection tubes use PET (polyethylene terephthalate) for its transparency, durability, and chemical resistance. You also prepare additives like EDTA K2, EDTA K3, lithium heparin, sodium heparin, sodium citrate, clot activator, silicone, and separation gel. These additives play a vital role in preserving samples for various assays, especially coagulation assays.

Industry standards require all materials to be free from contaminants. Even minor impurities can affect test results, especially in sensitive coagulation assays. The table below summarizes the purity requirements:

| Material Type | Purity Requirement | Notes |

|---|---|---|

| Plastic | High quality, free from contaminants | Affects test results |

| Glass | High quality, free from contaminants | Affects test results |

| Rubber Stoppers | High quality, free from contaminants | Affects test results |

You rely on Topkey’s automated systems to ensure consistent material quality. These systems help you maintain strict standards for every batch of vacuum blood collection tubes.

You move to the next step in the step-by-step guide to manufacturing vacuum blood collection tubes: tube formation. For plastic blood collection tubes, you use injection molding. This process creates tubes with uniform thickness and smooth interiors, which are essential for accurate assays and reliable coagulation testing. If you manufacture vacutainer glass citrate tubes, you use glass-blowing techniques to achieve precise volume markings and consistent tube dimensions.

Topkey’s advanced molding equipment ensures each tube meets exact specifications. You benefit from automation that reduces human error and increases production speed. You also form caps and stoppers using similar molding processes, which ensures a tight seal for your samples.

You now focus on applying additives to the interior of the tubes. This step is critical for preparing vacuum blood collection tubes for specific assays, such as coagulation assays that require citrate or EDTA. You use ultrasonic spray technology to coat the inside walls evenly. This method sprays silica or other additives as a fine mist, forming a uniform thin film. The ultrasonic vibration breaks apart any clumps, ensuring a homogeneous layer. This even distribution is vital for assays that measure coagulation, as it prevents inconsistent results.

You prepare vacutainer glass citrate tubes and plastic blood collection tubes with precise amounts of citrate or other additives. This accuracy supports reliable coagulation assays and preserves the integrity of your specimens. You can trust Topkey’s automation to deliver consistent additive application, which is essential for the advantages of vacuum blood collection tubes in clinical settings.

Tip: Even minor variations in additive coating can impact the accuracy of coagulation assays. Automated systems help you achieve the consistency needed for trustworthy results.

You complete these steps to manufacture vacuum blood collection tubes that support a wide range of assays, including those for coagulation. You ensure that blood-draw tubes meet the highest standards, so your samples remain stable and ready for laboratory analysis.

You now reach a critical stage in the production of vacuum blood collection tubes. Vacuum sealing ensures that each tube maintains the correct negative pressure, which allows you to draw the precise volume of blood during collection. You rely on advanced automation to remove air from the tubes and create a stable vacuum environment. This process is essential for both vacutainer and other vacuum blood collection tubes, as it guarantees consistent sample volumes and reliable test results.

During vacuum sealing, you place the tubes in specialized chambers. Automated systems evacuate the air and seal the tube, locking in the vacuum. You benefit from this technology because it reduces human error and increases production efficiency. Topkey’s equipment uses precise controls to monitor pressure levels throughout the process.

Quality control plays a vital role at this stage. You must verify that each tube maintains its vacuum integrity. The following table outlines the main quality control measures you implement during vacuum sealing:

| Quality Control Measure | Description |

|---|---|

| Testing for Vacuum Integrity | You conduct rigorous testing to assess vacuum integrity and overall quality. |

| Inspections | You perform regular inspections to monitor the integrity of each tube. |

| Material Quality | You ensure the quality of materials used in production remains high. |

You also follow these best practices to maintain high standards:

You verify tube manufacturing processes at every step.

You validate tube performance through systematic testing.

You monitor storage conditions to preserve vacuum stability.

You schedule regular inspection and maintenance of equipment.

Note: Consistent vacuum levels in vacuum blood collection tubes help you avoid underfilling or overfilling, which can compromise test accuracy.

By following these procedures, you ensure that every vacutainer and vacuum blood collection tube meets strict industry standards. You provide healthcare professionals with reliable blood-draw tubes that support accurate diagnostics.

After vacuum sealing, you move to cap installation. This step protects the sterile environment inside the tube and prevents contamination. You use automated machines to fit caps securely onto each tube. These machines apply uniform pressure, ensuring a tight seal that maintains the vacuum and keeps the sample safe.

You encounter several types of caps in the production of vacuum blood collection tubes. The table below shows common cap types, their sizes, additives, and closure mechanisms:

| Volume/ml | Size/mm | Additive | Cap Color | Closure |

|---|---|---|---|---|

| 2ml | 13X75 | Lithium Heparin / Sodium Heparin | Green Top Tube | Safety Cap + Rubber Stopper |

| 2ml | 13X75 | EDTA K2 / EDTA K3 | Purple Cap Tube | Safety Cap + Rubber Stopper |

| 1.6ml/1.28ml | 8×120 | 3.8% Sodium Citrate | Black Top Tube | Safety Cap + Rubber Stopper |

| 2ml | 13X75 | Clot Activator | Orange Cap Tube | Safety Cap + Rubber Stopper |

| 2ml | 13X75 | Clot Activator | Gold Top Tube | Safety Cap + Rubber Stopper |

You select the cap based on the tube’s intended use and additive. Safety caps with rubber stoppers are standard because they provide a secure closure and allow for easy needle penetration during blood collection. You ensure that each cap fits perfectly, preserving the vacuum and preventing leaks.

Tip: Always check that the cap is properly installed before using vacuum blood collection tubes. A secure cap maintains sterility and vacuum, which are essential for accurate laboratory results.

By completing these steps, you produce vacuum blood collection tubes that meet the highest standards for safety and reliability. You support healthcare professionals by delivering tubes that perform consistently in every clinical setting.

Modern production of blood collection tubes relies on advanced automation. You depend on specialized machines to ensure every tube meets strict standards for assays, especially those involving coagulation. These machines help you maintain consistency, speed, and accuracy when preparing samples for laboratory analysis.

You use the automatic blood collection tube assembly machine to streamline the entire manufacturing process. This machine assembles plastic blood collection tubes, adds the correct amount of citrate or other additives, and ensures each tube is ready for use in coagulation assays. You benefit from high-speed production, which allows you to meet the growing demand for vacuum blood collection tubes and vacutainer products.

| Feature | Benefit |

|---|---|

| High-Speed Production | You can produce thousands of tubes per hour, increasing output for blood-draw tubes. |

| Integrated Pre-Labeling | Automated labeling reduces errors and keeps labeling consistent for all samples. |

| Labor Cost Reduction | Automation lowers labor costs and boosts production efficiency. |

| Improved Productivity | Shorter production cycles help you meet customer needs for coagulation testing. |

You also save time during sample collection, which leads to faster and more accurate results for assays, including those that require precise citrate levels.

You rely on the blood collection tube UV printing machine to label tubes quickly and accurately. This machine prints directly onto plastic blood collection tubes, ensuring that information stays clear and legible throughout the handling of specimens and samples. UV printing supports automated production lines and keeps up with the speed of modern manufacturing.

| Advantage | Description |

|---|---|

| Cost-effectiveness | UV printing costs less than traditional labels. |

| Durability | Printed text resists peeling and fading. |

| Compatibility | You can install this machine on automated lines. |

| Speed | Prints up to 12,000 tubes per hour. |

You avoid label mix-ups, which is critical for assays that depend on accurate sample identification, such as coagulation assays and vacutainer-based tests.

You use the 360° vision inspection system to check every tube for defects. This machine examines plastic blood collection tubes from all angles, ensuring that each one meets quality standards before it reaches the laboratory. You catch imperfections that could affect the accuracy of assays, especially those for coagulation or citrate-based testing.

You inspect for cracks, irregularities, or improper additive distribution.

You verify that each tube is ready for use in sensitive coagulation assays.

You ensure that vacuum blood collection tubes and vacutainer products maintain their integrity for reliable results.

Tip: Automated inspection helps you deliver blood collection tubes that support precise assays and protect the quality of all samples and specimens.

By using these advanced machines, you guarantee that every step in the production of blood collection tubes supports the accuracy and reliability needed for coagulation assays and other laboratory tests.

You play a crucial role in ensuring the reliability of vacuum blood collection tubes. Quality control and packaging standards protect both your samples and the accuracy of your assays. Every step in the manufacturing process must meet strict protocols to guarantee that tubes support sensitive coagulation testing and other laboratory assays.

You start by testing raw materials. You check for contaminants and confirm that each batch meets precise specifications. This step prevents impurities from affecting your specimens or interfering with coagulation assays. You then validate the manufacturing process. You confirm that each stage produces tubes that meet safety and performance requirements for all types of assays.

| Component | Description |

|---|---|

| Raw material testing | Testing raw materials for quality and consistency, including contaminants and specifications. |

| Process validation | Validating the manufacturing process to ensure consistent production of safe and accurate tubes. |

| Finished product testing | Rigorous testing of manufactured tubes for leaks, breakage, contamination, and compatibility. |

| Quality control documentation | Maintaining documentation of all quality control measures for reference and compliance. |

| Good Manufacturing Practices | Compliance with GMP regulations for safe and controlled manufacturing environments. |

| ISO 13485 certification | Certification demonstrating effective quality management systems specific to medical devices. |

| Product labeling requirements | Ensuring proper labeling of tubes with essential information for correct usage and handling. |

You inspect every tube for common defects. You look for leaks, cracks, and improper additive distribution. You also check for issues with tube caps and sealing. These inspections help you avoid problems that could compromise your samples or disrupt coagulation assays.

You use proper techniques for collecting blood samples.

You follow correct handling and storage procedures for tubes.

You recognize common defects in tubes.

You respond quickly to incidents of tube contamination or breakage.

You face several challenges in maintaining the reliability of vacuum blood collection tubes. You must ensure proper sealing to prevent evaporation and contamination. You inspect tube caps regularly to avoid defects that could affect the seal. You store tubes according to guidelines to maintain their integrity. You train staff to handle tubes carefully, reducing the risk of breakage or contamination.

| Challenge | Explanation |

|---|---|

| Lack of proper sealing technique | Improper sealing can lead to sample evaporation, contamination, and loss of sample integrity. |

| Defective tube caps | Damaged or worn caps can compromise the seal, necessitating regular inspection and replacement. |

| Storage conditions | Improper storage can deteriorate the seal, leading to leaks; tubes should be stored as per guidelines. |

| Handling errors | Rough handling can break seals, causing contamination; proper training on handling is essential. |

You follow international standards such as ISO 13485. This standard requires you to maintain a quality management system, manage risks, and ensure traceability for all vacuum blood collection tubes. You document every step, from raw material testing to finished product inspection. You label each tube clearly, supporting accurate identification for all assays, including coagulation and other specialized tests.

| Key Aspect | Description |

|---|---|

| Quality Management System (QMS) | ISO 13485 emphasizes the need for a QMS that aligns with regulatory requirements. |

| Risk Management | The standard regulates the risk management approach to product realization and development. |

| Product Traceability | It mandates efficient product traceability and recall systems. |

| Compliance | Ensures statutory and regulatory compliance for medical devices. |

| Certification Benefits | Certification demonstrates that companies meet mandatory regulatory obligations, enhancing credibility and reducing legal risks. |

You maintain high standards for quality control and packaging. You protect your samples and ensure that every tube supports accurate coagulation, chemistry, and hematology assays. Your commitment to quality safeguards the integrity of all specimens and supports reliable results in every laboratory setting.

You see the global market for blood collection tubes expanding rapidly. In 2024, the market reached USD 6.89 billion. By 2032, experts project it will grow to USD 11.40 billion, with a compound annual growth rate of 6.50%. Several factors drive this demand.

Chronic diseases like diabetes, cancer, and heart conditions require frequent blood tests. You need reliable tubes to collect and analyze these samples.

An aging population increases the need for diagnostic services. Older adults often need regular monitoring, which boosts the use of vacuum blood collection tubes.

Medical technology advances every year. New diagnostic tests appear, and you must collect more samples for these procedures.

Healthcare infrastructure grows in emerging economies. Hospitals and clinics invest in better equipment, including vacuum blood collection tubes, to improve patient care.

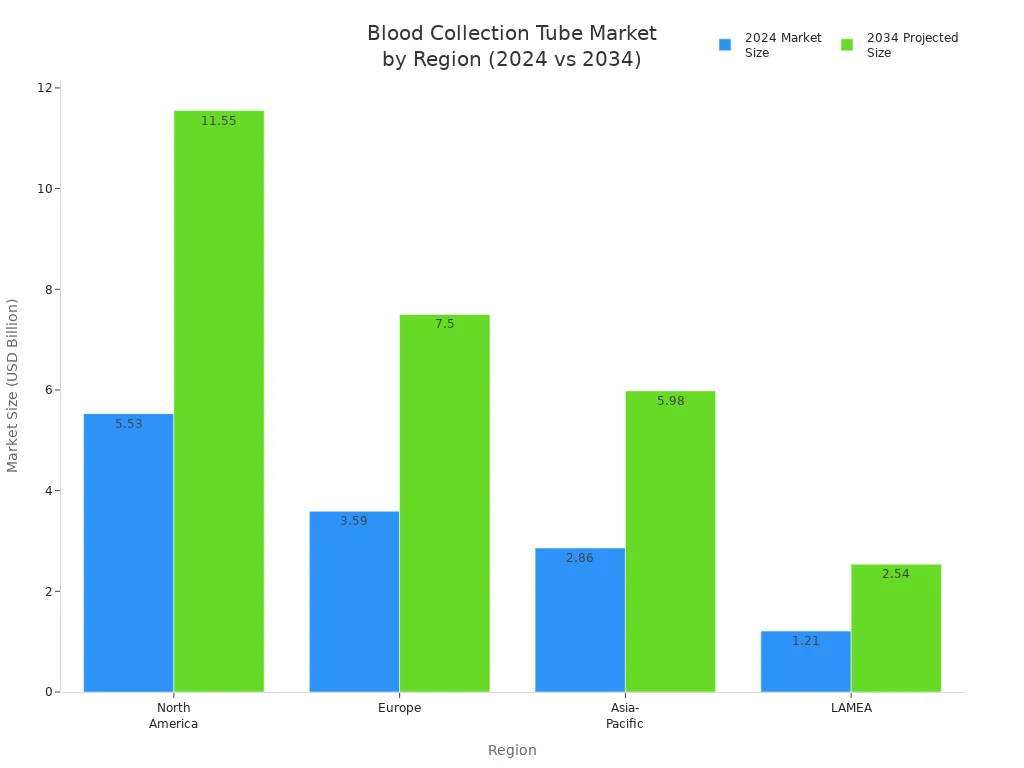

Regional differences also shape the market. You notice North America leads with a well-developed healthcare system and high investment in innovation. Europe follows with strict safety standards and high demand due to infectious diseases. Asia-Pacific sees growth from rising healthcare spending and population increases. LAMEA regions improve access and awareness, driving further demand.

| Region | Market Size (2024) | Projected Size (2034) | Key Factors Affecting Demand and Supply |

|---|---|---|---|

| North America | USD 5.53 billion | USD 11.55 billion | Well-developed healthcare system, high investment in medical innovation, high prevalence of chronic diseases. |

| Europe | USD 3.59 billion | USD 7.50 billion | Stringent regulatory norms, emphasis on patient safety, high demand due to infectious disease occurrences. |

| Asia-Pacific | USD 2.86 billion | USD 5.98 billion | Increasing healthcare expenditure, population growth, and awareness regarding health issues related to blood. |

| LAMEA | USD 1.21 billion | USD 2.54 billion | Developing healthcare sectors, improving health access, and growing awareness and investments in healthcare. |

You observe several trends shaping the future of vacuum blood collection tubes. Safety and sustainability now guide design choices. Manufacturers invest in antimicrobial coatings and improved sealing to reduce contamination risks. You benefit from eco-friendly tubes made with recycled plastics or biodegradable materials, which help lower carbon emissions and energy costs.

Production technology evolves quickly. You see advanced materials like titanium and carbon fiber composites making tubes stronger and lighter. Automation and robotics speed up manufacturing and improve quality control. Smart manufacturing uses IoT and AI to monitor production in real time, ensuring every tube meets strict standards.

You notice the market for vacuum blood collection tubes growing at a projected CAGR of 5.9% from 2024 to 2029, with an increase of USD 735.6 million. As healthcare needs rise, you rely on these tubes to collect and protect samples for accurate testing. Manufacturers respond by developing innovative solutions that support your work and meet global demand.

Tip: Choose vacuum blood collection tubes with advanced safety features and sustainable materials to support both patient care and environmental responsibility.

You oversee each stage of blood tubes production, from material selection to vacuum sealing and cap installation. Automation boosts consistency and production capacity, as shown below:

| Automation Feature | Impact on Production |

|---|---|

| Precision and reduced error | Consistent quality |

| Built-in quality control | Higher capacity, reliable output |

Vacuum blood collection tubes offer minimized patient discomfort, safety for healthcare professionals, and improved blood sample preservation. You experience the benefits of vacuum blood collection tubes through accurate results and optimized workflow. The advantages of vacuum blood collection tubes support your daily practice. Partnering with a trusted manufacturer like Topkey ensures you receive reliable vacuum blood collection tubes for every need.

You usually see medical-grade plastics like PET or glass. Manufacturers select these materials for their strength, clarity, and chemical resistance. These choices help you maintain sample integrity and ensure accurate laboratory results.

You use color-coded caps to identify the additives inside each tube. Each color signals a specific test type or preservative. This system helps you select the correct tube quickly and reduces the risk of errors during sample collection.

Manufacturers use automated equipment and sterile environments. You benefit from processes like gamma irradiation or ethylene oxide sterilization. These methods keep tubes free from contaminants and protect your samples from infection.

The vacuum draws a precise amount of blood into the tube. You rely on this feature for accurate sample volumes. Consistent vacuum levels help you avoid underfilling or overfilling, which can affect test results.

You should never reuse blood collection tubes. Single-use design prevents cross-contamination and ensures patient safety. Always dispose of used tubes according to medical waste guidelines.

You store tubes in a cool, dry place away from direct sunlight. Keep them in their original packaging until use. Proper storage helps you maintain sterility and vacuum integrity.

You look for manufacturers who comply with ISO 13485 and Good Manufacturing Practices (GMP). These standards ensure consistent quality, traceability, and safety for every batch of blood collection tubes.

Automation increases production speed and consistency. You benefit from fewer human errors, better quality control, and reliable tube performance. Automated systems also support advanced inspection and labeling processes.