- Home

- Products

- Consumable

- Capabilities

- Service

- Videos & News

- About

- Contact Us

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

Did you know that the AVF Needle size is critical for effective fistula dialysis? Choosing the right needle ensures both patient comfort and treatment efficiency. In this article, we will explore the different needle sizes used in dialysis and how they impact patient care. You’ll also learn how Topkey Medical’s AVF Needle Assembly Machine ensures precision in needle production.

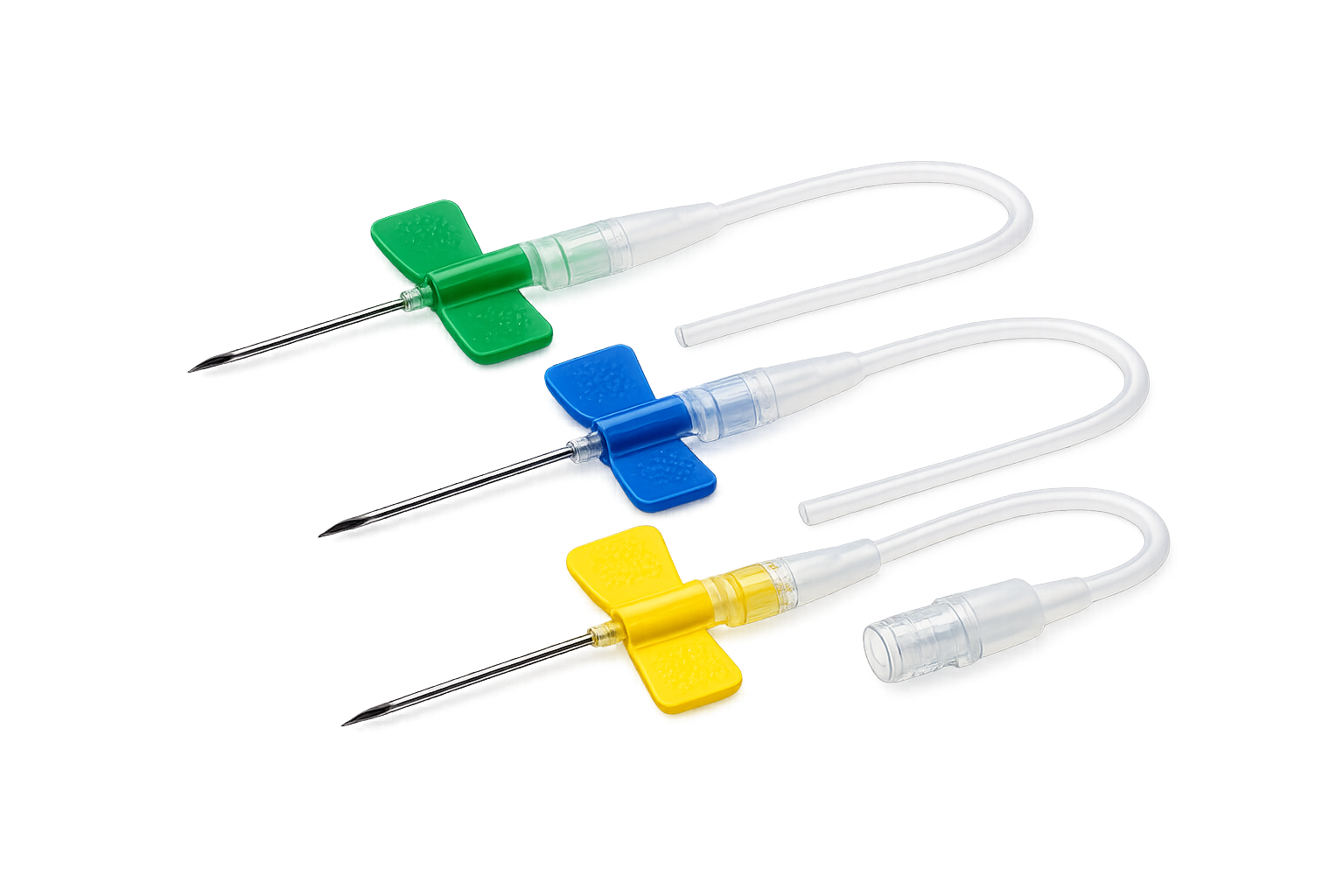

An AVF Needle (Arteriovenous Fistula Needle) is a crucial tool used in hemodialysis to access a patient’s blood vessels during the dialysis process. It creates a stable connection between the dialysis machine and the bloodstream, enabling efficient filtration and waste removal. These needles are designed to be inserted into the arteriovenous fistula, a surgically created connection between an artery and vein, providing a reliable access point for the dialysis procedure.

● Long-term Dialysis Use: AVF needles are specifically designed for long-term dialysis treatments, offering a secure and effective solution for patients with kidney failure. They are essential in ensuring effective blood flow and patient comfort during the process.

The most common AVF needle sizes used in dialysis are 15G, 16G, and 17G. The choice of needle size depends on factors such as the patient's vein condition, blood flow requirements, and the desired dialysis speed.

● 15G is typically used for patients who require higher blood flow rates.

● 16G is the most commonly used size for adult dialysis.

● 17G is ideal for pediatric patients or those with delicate veins.

● 15G – Ideal for higher blood flow rates (350–450 mL/min), making it suitable for patients with thicker veins needing a higher volume of blood to be processed.

● 16G – Most commonly used for adult patients (250–350 mL/min), offering a balance between adequate blood flow and patient comfort.

● 17G – Best for delicate veins or pediatric patients (200–250 mL/min), ensuring gentle access with minimal discomfort.

Needle Size (Gauge) | Blood Flow Rate (mL/min) | Common Use |

15G | 350–450 | High-efficiency dialysis |

16G | 250–350 | Standard adult use |

17G | 200–250 | Pediatric and fragile veins |

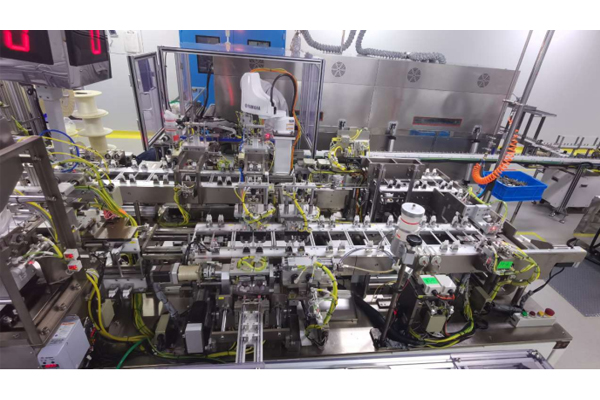

Topkey Medical offers advanced AVF Needle Assembly Machines designed to efficiently produce 15G, 16G, and 17G needles. These machines combine automation and precision to streamline the needle assembly process, ensuring the production of high-quality AVF needles suitable for hemodialysis.

● Precision in Production: The assembly machine guarantees that each AVF Needle is made to exact specifications, reducing the potential for defects.

● High Efficiency: Automated systems enhance production speed while maintaining consistency in each needle produced.

Topkey Medical's AVF Needle Assembly Machine comes equipped with several innovative features designed to improve efficiency, quality, and consistency during the needle assembly process.

Feature | Benefit |

Automated Feeding Systems | Ensures accurate and efficient assembly, reducing human error. |

Vision Inspection Systems | Provides real-time quality checks, ensuring each needle meets medical standards. |

Adhesive Dispensing and Silicone Oil Coating | Seamlessly integrates these processes to create reliable and smooth needle assemblies. |

● Automated Feeding Systems: The feeding systems automatically supply components, such as needle tubes and needle hubs, to the assembly line, ensuring that each part is positioned correctly before the assembly begins.

● Vision Inspection Systems: These systems inspect the needle tip, glue application, and alignment, ensuring no defective products reach the final stages.

● Seamless Integration of Processes: The machine automatically applies adhesives and silicone oil coatings, reducing the need for manual intervention while maintaining high-quality standards.

By integrating these key features, Topkey Medical's AVF Needle Assembly Machine ensures that every needle produced is of the highest quality, supporting the growing demand for reliable dialysis treatments.

The vision inspection systems play a vital role in ensuring that every AVF Needle produced meets medical standards. These systems are designed to inspect every needle for defects, ensuring precision in alignment, glue application, and needle tip quality.

● Defect Detection: Vision inspection ensures that needles are checked for issues like improper glue application, misalignment, or needle tip irregularities.

● Topkey Medical's Advanced Technology: Topkey Medical’s assembly machine uses state-of-the-art CCD cameras, offering high precision and reliability during the inspection process. These cameras capture detailed images to detect even the smallest defects, improving overall quality control.

Feature | Benefit |

CCD Cameras | Provides detailed, high-precision inspection for each needle. |

Real-Time Monitoring | Detects defects immediately, ensuring only defect-free needles are produced. |

Topkey Medical’s AVF Needle Assembly Machine integrates an automated system to guarantee that only qualified products make it to the packaging stage.

● Automated Rejection of Defective Needles: As part of the automated inspection process, any defective needles are automatically rejected, preventing them from moving forward in the assembly line. This eliminates the risk of faulty products reaching customers.

● Consistent Quality Across Large Production Runs: The automated system ensures consistent quality across high-volume production, helping manufacturers scale up operations without compromising the quality of each AVF Needle.

Process | Outcome |

Automated Rejection | Only defect-free products are allowed to proceed. |

High-Volume Consistency | Ensures consistent quality during large-scale production runs. |

This integrated approach provides a reliable, high-quality solution for manufacturers, enabling them to meet growing demand for AVF Needles while maintaining the highest standards in dialysis treatments. Topkey Medical ensures that its automated systems are equipped to handle quality control at every step of the production process.

Automated systems bring unmatched precision and consistency in the production of AVF needles. These systems are designed to minimize human error, ensuring that every needle is produced to the highest standards.

● Precision Assembly: Topkey Medical ensures consistent precision by integrating vision systems and digital control, making each needle meet the required medical specifications.

● Automated Checks: The vision systems provide real-time monitoring, ensuring that every aspect of the needle, from alignment to glue application, is checked for defects.

Feature | Benefit |

Vision Systems | High-precision inspection guarantees defect-free needles. |

Digital Control | Ensures accurate assembly and consistency in production. |

Topkey Medical’s AVF Needle Assembly Machines are designed to handle high-volume production, reducing assembly time significantly.

● Faster Production: Automation ensures the assembly process is quick, allowing for more units to be produced in less time.

● Catering to High Demand: These machines can keep up with high-demand markets for AVF needles, meeting the needs of large-scale dialysis providers.

Benefit | Impact on Production |

Faster Assembly | Increases throughput and reduces production time. |

Scalable Production | Allows for high-volume production with consistent quality. |

One of the key benefits of automation in AVF needle assembly is the reduction in manual labor and improvement in production speed, which leads to significant cost savings.

● Lower Labor Costs: By reducing the need for manual assembly, Topkey Medical's machines decrease the overall labor required.

● Cost-Effective Manufacturing: Faster production times and higher output result in lower overall manufacturing costs.

Benefit | Cost Impact |

Reduced Labor | Lowers operational costs due to less manual involvement. |

Faster Production | Higher output means more products for less cost. |

The size of the AVF Needle selected for dialysis depends on various factors, including the dialysis needs and the patient’s anatomy.

● Healthcare providers assess each patient’s needs to determine which needle size will deliver optimal results. Topkey Medical’s machine can handle multiple AVF Needle Sizes, including 15G, 16G, and 17G, ensuring that the right size is chosen for each patient.

Needle Size (Gauge) | Common Use | Ideal For |

15G | High-efficiency dialysis | Patients requiring high blood flow rates |

16G | Standard adult use | Suitable for most adult patients |

17G | Pediatric or delicate veins | Pediatric patients or those with fragile veins |

Some patients, particularly those with pediatric needs or fragile veins, require smaller gauge needles. 17G needles are ideal for such cases, providing a balance between needle size and blood flow rate.

● 15G needles are typically used for patients requiring higher blood flow and more robust dialysis treatments.

● Topkey Medical’s machines are adaptable, producing AVF needles in varying sizes for both standard and specialized applications, ensuring that the right solution is available for every patient.

Topkey Medical has over 20 years of experience in delivering automated production solutions for medical consumables and devices, specializing in the AVF needle assembly process. The company is a leader in providing high-precision machinery that meets the demand for high-quality AVF needles in hemodialysis.

● Proven Expertise: With decades of experience, Topkey Medical brings advanced manufacturing solutions tailored for the medical sector, particularly for dialysis equipment.

● Commitment to Quality: The company’s focus on quality control and precision manufacturing ensures that each AVF needle meets the highest medical standards.

Topkey Medical’s AVF Needle Assembly Machines are designed with advanced features to improve efficiency, consistency, and precision in needle production. These machines provide automated, high-quality solutions for the hemodialysis industry.

● High Throughput: These machines are capable of high-volume production, ensuring manufacturers can meet the growing demand for AVF needles without compromising on quality.

● Precision Manufacturing: The machines adhere to strict medical standards for needle assembly precision, ensuring that every needle is made to exact specifications.

● Real-Time Data Collection: The machines are equipped with real-time monitoring systems, allowing for continuous production tracking and quality assurance.

Feature | Benefit |

Automated Vision System | Ensures that only defect-free needles reach the final stage of production. |

Flexible Needle Sizes | Capable of producing 15G, 16G, and 17G needles to meet different medical requirements. |

High Efficiency | Allows for faster production without sacrificing precision, ideal for high-demand markets. |

● Automated Vision System: The vision inspection system ensures that every needle meets quality standards, from tip alignment to glue application.

● Flexible Needle Sizes: The machine supports a wide range of AVF needle sizes, making it adaptable for various dialysis requirements. Whether for pediatric or adult patients, Topkey Medical’s machines can produce needles of all sizes, including 15G, 16G, and 17G.

● Efficient Production: With high production efficiency, the machines minimize downtime and maximize output, allowing manufacturers to meet the needs of the hemodialysis market quickly.

Topkey Medical’s AVF Needle Assembly Machines offer an efficient, cost-effective solution for producing AVF needles at scale, ensuring precision, consistency, and high-quality standards.

The article explains the importance of selecting the right AVF Needle size based on patient needs and dialysis treatment goals. Topkey Medical provides advanced solutions with its AVF Needle Assembly Machines, ensuring precision and efficiency in needle production. These machines offer high throughput, quality control, and cost-saving benefits for manufacturers.

A: AVF needles commonly used for fistula dialysis include 15G, 16G, and 17G, with size selection based on blood flow requirements and vein condition.

A: The AVF Needle Assembly Machine automates the assembly process, ensuring precise needle manufacturing with high throughput and quality control.

A: Needle size selection depends on vein size, patient comfort, and blood flow requirements, with 15G for high flow and 16G, 17G for delicate veins.

A: AVF Needle manufacturing must meet strict medical standards to ensure safety, comfort, and consistency, particularly for long-term dialysis treatments.

A: The AVF Needle Assembly Machine improves production efficiency by reducing assembly time, minimizing human error, and increasing output without compromising quality.