- Home

- Products

- Consumable

- Capabilities

- Service

- Videos & News

- About

- Contact Us

Please Choose Your Language

Did you know that a clean environment is crucial for producing high-quality AVF Needles? In this article, we’ll explore the essential role of scrubber machines in medical device manufacturing. You’ll learn how scrubbers improve cleanliness, reduce contamination risks, and contribute to the efficient production of AVF Needles.

Scrubber machines are integral to maintaining clean, contaminant-free environments in industries like AVF Needle manufacturing. These machines help filter out dust, airborne particles, and other contaminants that could compromise product quality and safety. In medical device production, such as AVF Needles, ensuring cleanliness is essential for both efficiency and the safety of the final product.

● Purpose of scrubbers: Scrubber machines remove particles and pollutants from the air, helping to maintain a sterile environment in production areas.

● Types of scrubbers:

Wet scrubbers: Use liquid to trap contaminants, ideal for environments where moisture control is necessary.

Dry scrubbers: Rely on dry chemicals or media to capture airborne particles, making them suitable for low-humidity environments like cleanrooms.

Scrubber Type | Functionality | Best Use Case |

Wet Scrubber | Removes dust and gases using liquid | Medical cleanrooms, wet environments, AVF Needle manufacturing |

Dry Scrubber | Captures particles using dry chemicals | Environments requiring low humidity, sterile production areas |

Maintaining cleanliness is not just about quality control—it also directly influences the efficiency of the manufacturing process. Scrubber machines help create an optimal environment where production can flow seamlessly without contamination-related disruptions.

● Benefits of cleanliness in production lines:

Reduces downtime caused by contamination or quality control issues.

Ensures consistent quality, especially when producing precise products like AVF Needles.

Helps avoid unnecessary repairs or rework, which can disrupt production schedules.

● Impact on AVF Needle manufacturing:

A clean environment ensures that every AVF Needle produced meets the required precision and hygiene standards.

Scrubber machines prevent particles that could interfere with the needle assembly, minimizing defects and errors.

For AVF Needles, which are used in life-saving treatments like hemodialysis, cleanliness is critical to ensure both the safety of the patient and the functionality of the device. Contamination can result in serious complications, such as infections, clotting, or malfunctioning needles.

● Key hygiene considerations:

Contaminants can affect the structure of AVF Needles, potentially making them ineffective or unsafe for patient use.

Maintaining a sterile environment prevents the introduction of harmful bacteria or foreign particles into the bloodstream.

● Precision and functionality:

Contaminants can alter the performance of AVF Needles, leading to issues like improper insertion or blood flow disruptions during dialysis.

Cleanliness ensures that needles are manufactured with the precise dimensions and functionality required for effective dialysis.

The role of scrubber machines in AVF Needle Assembly Machines is crucial. These machines need to operate in a contamination-free environment to ensure that each needle meets the highest safety and quality standards.

● How scrubbers contribute:

Scrubber machines help keep the air free from particulate matter that could land on the AVF Needles during assembly.

By filtering out contaminants, scrubbers prevent particles from interfering with the delicate needle manufacturing process.

● Maintaining biocompatibility:

AVF Needles must be biocompatible, meaning they cannot introduce harmful substances into the body. Scrubbers help maintain this standard by reducing the risk of contamination during production.

They ensure that all parts of the needle assembly process, from the needle hub to the silicone coating, are free of contaminants that could affect patient safety.

Scrubber machines are vital in medical device manufacturing, especially for sensitive products like AVF Needles. These machines ensure that the environment is sterile and contaminant-free, which is essential for maintaining the quality and safety of medical devices used in life-saving procedures like hemodialysis.

● HEPA Filters: High-efficiency particulate air (HEPA) filters are crucial for removing airborne particles and ensuring that the air remains clean and safe for production.

● Air Circulation Systems: Scrubbers use advanced air circulation systems to ensure that clean, filtered air is consistently circulated throughout the production area, maintaining a sterile environment.

● Contaminant Removal: Scrubbers are designed to remove a wide range of contaminants, from dust to volatile organic compounds (VOCs), which could otherwise compromise the production of AVF Needles.

These features are essential in maintaining the high standards required for producing AVF Needles, ensuring that every batch is manufactured in a safe, clean, and efficient environment.

Maintaining cleanliness in the AVF Needle production line is crucial for both the quality of the product and patient safety. Scrubber machines play a vital role in keeping the environment free of contaminants that could affect the assembly process and the final product.

● Preventing Contamination: Scrubber machines help ensure that there are no airborne particles or dust that could interfere with the delicate assembly of AVF Needles. This is especially important for needles, as even small particles can affect their functionality or biocompatibility.

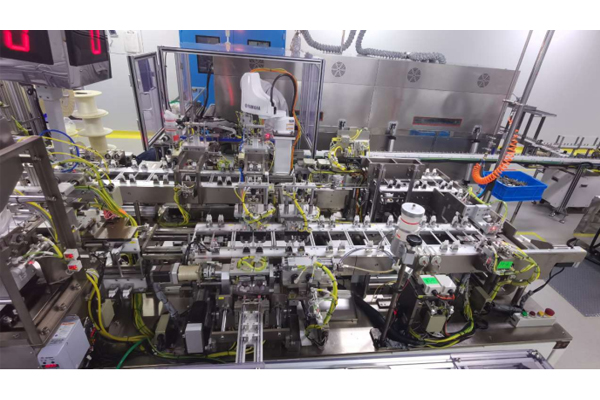

● Integration with Topkey Medical’s AVF Needle Assembly Machines: Scrubbers are integrated into Topkey Medical’s advanced AVF Needle Assembly Machines**, ensuring that the manufacturing process maintains the highest standards of cleanliness. This integration ensures optimal performance and reduces the risk of contamination during assembly.

Feature of Scrubber | Benefit for AVF Needle Manufacturing |

HEPA Filters | Removes fine airborne particles, ensuring sterile conditions for needle assembly. |

Air Circulation | Ensures even distribution of filtered air, preventing local contamination. |

Automated Cleaning | Reduces human error, providing consistent and reliable cleaning performance. |

When choosing a scrubber machine for AVF Needle production, understanding the differences between wet and dry scrubbers is essential. Both types have their advantages depending on the specific needs of the manufacturing environment.

● Wet Scrubbers:

Pros: Effective at removing particles, gases, and odors. Ideal for medical environments where humidity control is essential.

Cons: Require maintenance of moisture levels and can lead to water waste if not managed properly.

● Dry Scrubbers:

Pros: Efficient at removing particulate matter without the need for water. Ideal for dry environments, such as those in sterile production areas.

Cons: May be less effective in removing gases or odors compared to wet scrubbers.

Scrubber Type | Pros | Cons | Ideal Use Case |

Wet Scrubber | Removes gases, dust, and odors efficiently | Requires moisture control and maintenance | AVF Needle manufacturing with controlled humidity |

Dry Scrubber | No moisture needed, better for dry environments | Less effective at removing gases | Cleanrooms requiring low humidity for sterile production |

Selecting the right scrubber machine is crucial to maintaining a clean environment in the AVF Needle production line. Key factors to consider include the machine's airflow capacity, filtration efficiency, and ability to comply with industry regulations.

● Airflow Capacity: The scrubber’s airflow must match the size of the production facility. A higher airflow ensures that larger areas can be cleaned effectively and efficiently.

● Filtration Efficiency: For environments producing AVF Needles, high filtration efficiency is essential to ensure that even the smallest particles are captured and removed from the air.

● Compliance with Cleanroom Standards: It’s vital to select scrubber machines that meet cleanroom standards and regulatory guidelines. Compliance ensures that the production line remains sterile and free from contaminants, in line with industry regulations.

In medical environments, scrubber machines equipped with HEPA filters play a critical role in maintaining a sterile atmosphere, especially in sensitive manufacturing areas like AVF Needle production lines. HEPA filters trap airborne particles, such as dust, bacteria, and other contaminants, ensuring that only clean air circulates in the production area.

● How HEPA filters contribute to a sterile environment:

○ HEPA filters capture 99.97% of particles as small as 0.3 microns, effectively removing harmful particles that could affect the AVF Needle manufacturing process.

○ These filters are vital in environments where even the smallest contamination could cause defects in AVF Needles, impacting their performance in dialysis treatments.

● Effectiveness in AVF Needle production areas:

○ In Topkey Medical’s AVF Needle production lines, HEPA filters help maintain the cleanliness required for the precise assembly of needles used in dialysis.

○ By ensuring air purity, these filters prevent contamination that could lead to defects or make needles unsafe for patients.

The integration of automated cleaning cycles in scrubber machines brings a host of benefits, especially in medical device manufacturing. Automation ensures that cleaning processes are performed consistently and with minimal human intervention, which is crucial for maintaining high hygiene standards in environments like AVF Needle production.

● How automation improves cleanliness and reduces human error:

Automated scrubbers eliminate variability in cleaning processes, ensuring that every corner of the facility is equally well-maintained.

This technology reduces the risk of human error, such as missed spots or inconsistent cleaning, which is especially critical in medical device manufacturing.

● The benefits of automated systems in medical device manufacturing:

Topkey Medical uses automated scrubbers in their AVF Needle Assembly Machines to ensure that the entire production environment is regularly and efficiently cleaned.

These systems are designed to perform cleaning tasks at scheduled intervals, preventing contamination from building up between production shifts.

Feature of Scrubber | Benefit for AVF Needle Manufacturing |

HEPA Filters | Removes fine airborne particles, maintaining sterile conditions for needle assembly. |

Automated Cycles | Ensures consistent and reliable cleaning without human intervention, reducing errors. |

Air Circulation | Maintains uniform air quality and cleanliness across the production area. |

Scrubber machines are not just about cleanliness; they also contribute to sustainability in the production process. The latest scrubber models focus on energy efficiency and eco-friendly features, which can significantly reduce operational costs and environmental impact.

● How energy-efficient scrubber machines contribute to sustainability in production:

Modern scrubbers are designed to consume less energy while maintaining optimal cleaning performance.

These machines often feature advanced technology like variable speed motors, which adjust based on the cleaning needs of the environment, further conserving energy.

● Eco-friendly features of scrubbers:

Many scrubber machines now use environmentally friendly materials and less water in their cleaning cycles, making them a sustainable option for companies like Topkey Medical.

With growing concern about sustainability in the medical device industry, scrubbers with eco-friendly features are a key consideration in reducing a facility’s environmental footprint.

In the highly regulated world of medical device manufacturing, scrubber machines are essential for ensuring compliance with strict industry standards. Topkey Medical, for example, integrates scrubber machines that help meet both FDA and other medical safety standards by maintaining the required cleanliness levels in the production environment.

● How scrubbers help meet regulatory requirements in medical manufacturing:

Scrubber machines are equipped with features that ensure medical environments remain sterile, aligning with regulatory guidelines like FDA and ISO standards for manufacturing medical devices.

These standards require the prevention of contamination in environments where sensitive products, like AVF Needles, are made. Scrubbers play a vital role in meeting these standards by continuously filtering out contaminants.

● The importance of maintaining a sterile production environment for AVF Needles:

Maintaining a clean, sterile environment ensures that AVF Needles meet strict biocompatibility and safety standards. Contaminated environments could lead to compromised product safety, affecting patient health.

Scrubber machines are directly responsible for maintaining sterile production environments by removing pollutants and particles that could potentially cause contamination. In the case of AVF Needle production, maintaining such environments is crucial for ensuring product safety.

● The role of scrubbers in preventing cross-contamination:

Scrubbers help prevent cross-contamination by filtering the air and ensuring that no contaminants are introduced during the AVF Needle production process.

By keeping the production area clean, scrubbers ensure that every AVF Needle produced is free from particulate contamination.

● The link between cleanliness and product safety in Topkey Medical’s manufacturing process:

At Topkey Medical, scrubbers contribute to ensuring that their AVF Needle Assembly Machines operate in sterile conditions, which is critical for producing safe, high-quality needles used in dialysis treatments.

Clean, contaminant-free production lines lead to higher-quality products, minimizing risks and maximizing patient safety.

Scrubber Feature | Contribution to Compliance and Safety |

HEPA Filters | Captures airborne particles, ensuring sterile conditions for AVF Needle assembly. |

Automatic Cleaning | Ensures consistent cleanliness, reducing human error and contamination risks. |

Energy Efficiency | Complies with eco-friendly regulations while maintaining operational standards. |

Maintaining a sterile production environment is essential in medical device manufacturing, particularly when producing AVF Needles, which are used in critical procedures like hemodialysis. Scrubber machines play a key role in this by ensuring that the production area remains free from contaminants that could compromise the safety and effectiveness of the needles.

● How scrubbers help maintain a sterile environment, improving patient outcomes:

Scrubber machines equipped with HEPA filters and other advanced technologies ensure that no airborne particles, dust, or microorganisms enter the production line, reducing the risk of contamination.

For AVF Needles, a sterile environment helps guarantee that the needles are free from external pollutants, which is crucial for patient safety.

● Reducing contamination risks and enhancing needle performance:

Contamination during needle manufacturing can lead to defects, affecting the functionality of the AVF Needles during dialysis treatment. Scrubbers minimize this risk by continuously filtering the air and maintaining high cleanliness levels in the production area.

With reduced contamination risks, the AVF Needles are more reliable, ensuring better patient comfort and safer dialysis procedures.

While the initial investment in scrubber machines may seem significant, the long-term benefits they bring to the production process can result in substantial cost savings. Scrubbers improve operational efficiency and reduce the need for costly maintenance or rework on defective products.

● The long-term financial benefits of using scrubbers:

Scrubber machines help to reduce downtime caused by contamination-related issues, such as quality control failures or product recalls. With a consistent and clean production environment, manufacturing can proceed smoothly, increasing output and reducing costs.

The reduced need for manual labor to maintain cleanliness, along with fewer interruptions in production, also contributes to lower operational costs in the long term.

● How scrubbers help streamline the production process for AVF Needle manufacturing:

Scrubbers eliminate the need for additional cleaning steps, allowing the production team to focus on the assembly of AVF Needles. This streamlined process reduces time wasted on cleaning and ensures that the production line operates at maximum efficiency.

With automated cleaning cycles, scrubbers ensure a consistent environment, allowing Topkey Medical to maintain production schedules and meet deadlines, further improving efficiency.

In medical device manufacturing, product quality is paramount, and scrubber machines play a vital role in ensuring that AVF Needles are produced to the highest standards. By preventing contamination and maintaining a clean production line, scrubbers contribute to the overall quality and safety of the final product.

● How scrubbers contribute to consistent product standards in AVF Needle assembly lines:

By filtering out contaminants that could interfere with the needle manufacturing process, scrubbers help maintain the precision required in AVF Needle assembly. This ensures that each needle is made with consistent dimensions and meets the necessary performance standards.

Consistent cleanliness and air quality allow Topkey Medical to produce AVF Needles that are free from defects, improving both their functionality and safety for patients undergoing dialysis treatment.

Benefit of Scrubber | Contribution to AVF Needle Manufacturing |

Enhanced Needle Safety | Keeps the production environment sterile, reducing contamination risks and improving patient outcomes. |

Cost Savings & Efficiency | Streamlines the production process, reducing downtime and operational costs. |

Improved Product Quality | Ensures consistent product standards and reduces the likelihood of defects in AVF Needles. |

In this article, we’ve highlighted how scrubber machines contribute to maintaining sterile environments in AVF Needle production. Topkey Medical integrates advanced scrubber technology into their manufacturing lines to ensure optimal cleanliness, improving patient safety and product quality.

A: A scrubber machine is used to maintain a sterile environment by filtering out contaminants like dust and particles during the production of AVF Needles.

A: Scrubber machines ensure a clean, sterile environment, which minimizes contamination risks and enhances the safety and quality of AVF Needles used in dialysis.

A: Both wet and dry scrubbers are used, with wet scrubbers ideal for removing dust and gases, and dry scrubbers for particulate matter in low-humidity environments.

A: Cleanliness ensures that AVF Needles meet safety and quality standards, reducing the risk of infection and ensuring reliable performance in medical applications.

A: Scrubber machines provide consistent air quality, preventing contamination in the assembly area, and ensuring the proper functioning of AVF Needle assembly machines.