- Home

- Products

- Consumable

- Capabilities

- Service

- Videos & News

- About

- Contact Us

Please Choose Your Language

Views: 0 Author: Site Editor Publish Time: 2026-01-23 Origin: Site

Are you looking for the right AVF Needle machine for your business? Choosing the best machine is key to efficient production. In this guide, we’ll cover the cost, features, and factors to consider when buying an AVF Needle machine. You’ll learn how to make an informed decision based on your needs.

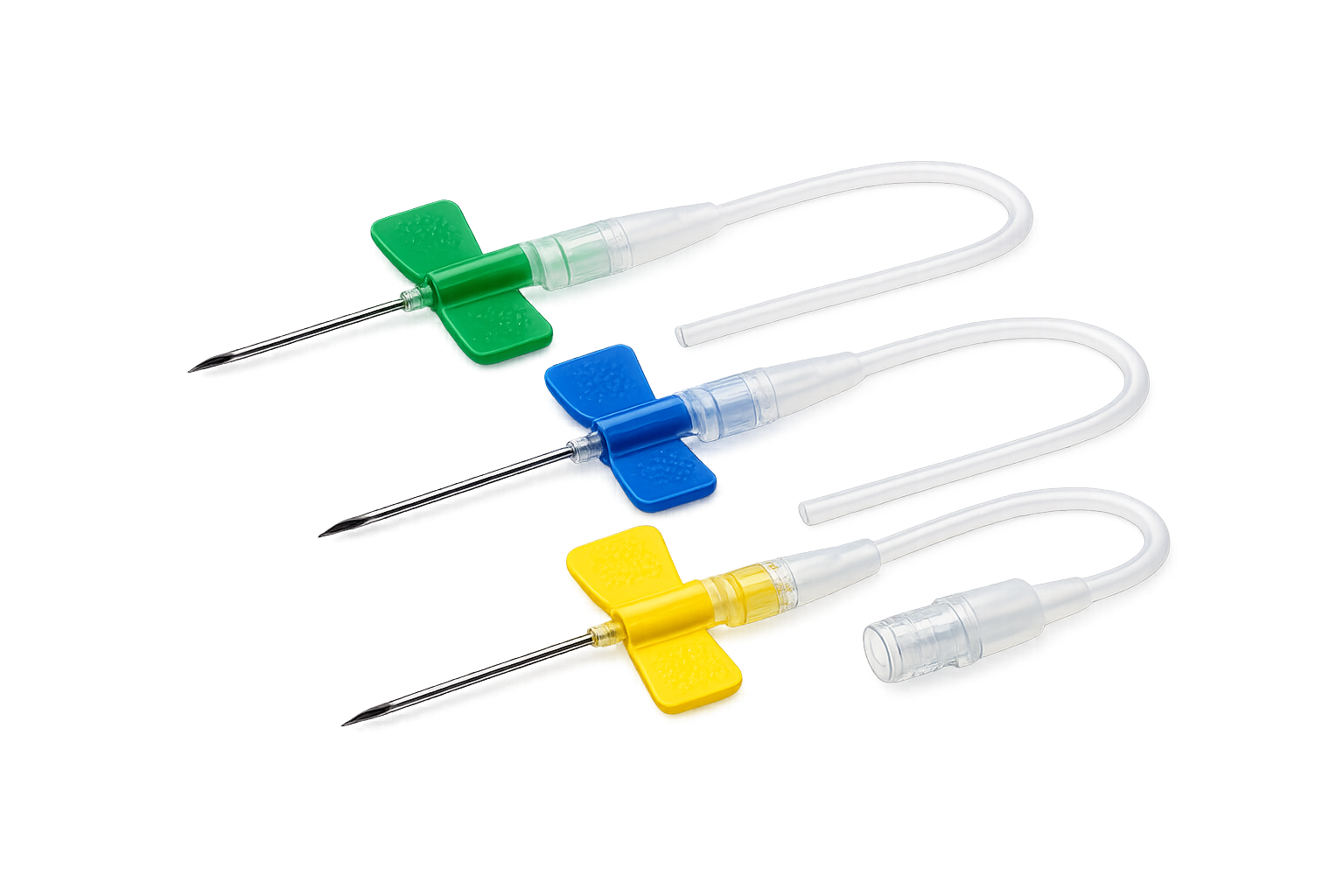

An AV Fistula Needle is used in hemodialysis to access a surgically created AV fistula, allowing blood to flow to a machine for purification and return to the body. The needle is designed to ensure smooth insertion and is durable for repeated use during dialysis treatments.

The quality of AVF needles is crucial for patient safety. Poor quality needles can lead to clotting or infections, which complicate dialysis. Topkey Medical machines ensure the production of high-precision AVF Needles, maintaining consistent quality and safety throughout the process.

● Needle Gauge and Length: Flexibility in needle sizes (e.g., 14G to 18G) helps meet varying patient needs.

● Material Quality: High-grade stainless steel ensures durability and reduces infection risks.

● Precision: Machines with vision inspection systems help maintain consistent needle quality.

Factor | Benefit |

Needle Gauge and Length | Customizes to patient needs |

Material Quality | Reduces infection risks |

Precision | Ensures consistent needle quality |

The level of automation in an AV Fistula Needle machine directly impacts its price. Machines that are fully automated tend to be more expensive compared to semi-automatic models. Fully automated systems, like those offered by Topkey Medical, enhance production efficiency by automating most of the tasks, reducing human labor costs, and ensuring consistent output quality.

● Semi-Automatic Machines: Typically require more manual labor and are less expensive.

● Fully Automated Machines: Increase efficiency, but come at a higher price due to advanced automation features.

Machines that are fully automated often come with a variety of advanced features, including:

● Robotic Feeders: For faster, more accurate placement of components.

● PLC Control: For precise control over the machine's operations.

● Vision Inspection Modules: Automatically detect defects during the production process, ensuring high-quality needle assembly.

Feature | Benefit |

Robotic Feeders | Increase speed and accuracy in needle assembly |

PLC Control | Ensures precise control and automation |

Vision Inspection | Enhances product quality and reduces defects |

Higher throughput machines, which are capable of producing a larger number of AVF Needles per hour, generally come with a higher price tag. For instance, machines that produce 2,000–3,500 pieces per hour are more expensive due to their advanced technology and higher production efficiency.

● Lower Output Models: Suitable for small to medium-scale production.

● High Throughput Models: More expensive but ideal for large-scale operations, ensuring a quick return on investment.

Before purchasing, it’s essential to evaluate your daily production requirements and match them with the machine’s capacity. Overestimating your needs could lead to unnecessary spending on a machine with excessive capacity, while underestimating may result in slower production.

Machines that come with integrated vision inspection systems play a vital role in ensuring the quality of each AVF Needle produced. By automatically detecting defects during the assembly process, these systems eliminate the need for manual inspections and reduce human error, ensuring that only high-quality needles pass through the production line.

Automated defect detection helps maintain low rejection rates and ensures that every Arteriovenous Fistula Needle meets the highest standards for medical use. Topkey Medical’s machines are equipped with these systems to ensure precise and reliable needle production, even at high speeds.

Inspection System | Function |

Vision Inspection | Detects defects during the production process |

Automated Control | Maintains consistency and quality at scale |

Some AV Fistula Needle machines are capable of producing needles in various sizes, from 14G to 36G, which can increase their cost. The engineering complexity required to support such flexibility adds to the machine's price, but the benefit is the ability to cater to a wide range of medical needs.

Machines that are customizable to handle specific Arteriovenous Fistula Needles types, such as straight or winged needles, also come at a higher cost. Customization adds value for manufacturers producing specialized needles but requires additional engineering and features.

Gauge Size Compatibility | Benefit |

Wide Range (14G–36G) | Allows for production of multiple needle sizes |

Customized Machines | Tailored for specialized needle types |

For smaller operations with lower throughput needs, basic automatic machines for manufacturing AVF Needles are often the most cost-effective choice. These machines can start from around US$15,000, making them accessible for smaller manufacturers or those just entering the market. Despite their lower cost, these machines are still capable of automating the needle assembly process, reducing labor and improving consistency. However, they may have limited features compared to their more expensive counterparts.

● Suitable for small-scale production with lower volume requirements.

● Basic automation for needle assembly.

● Limited gauge compatibility and slower throughput.

As production needs grow, mid-range machines become a practical choice for manufacturers aiming to increase efficiency and production speed. Fully automated machines, which include integrated inspection systems and support for multiple needle gauges, typically fall in the US$160,000–US$220,000 range. These machines offer higher throughput, allowing for the production of up to 2,000–3,500 needles per hour, making them suitable for larger-scale operations that require precision and higher volumes.

Feature | Entry-Level Machine | Mid-Range to Industrial-Grade |

Automation | Basic | Fully Automated |

Throughput (pcs/hour) | Lower (1,000–2,000) | Higher (2,000–3,500) |

Inspection System | Minimal or Manual | Integrated Vision Inspection |

Needle Gauge Compatibility | Limited (14G–16G) | Multiple Sizes (14G–36G) |

● Designed for medium to high-volume production.

● Higher precision and reliable output at scale.

● Vision inspection ensures quality during assembly.

For large-scale manufacturers requiring high-volume production, customized high-capacity machines are the best option. These machines are designed to meet specific operational needs and can cost upwards of US$500,000, depending on features such as advanced automation, custom gauge compatibility, and integration with other production lines. These systems are built for maximum efficiency, offering features like advanced robotic systems and automated packaging.

● Custom-built for large-scale production with high output needs.

● Designed for specialized Arteriovenous Fistula Needles with varying specifications.

● Often integrated with additional production lines for automated packaging and labeling.

Machine Type | Price Range (Approx.) | Features |

Entry-Level | ~US$15,000 | Basic automation, limited throughput |

Mid-Range to Industrial | US$160,000–US$220,000 | Fully automated, higher throughput |

High-Capacity Custom | US$500,000+ | Custom configurations, high efficiency |

When purchasing an AV Fistula Needle machine, the initial installation is a crucial cost to factor in. Installation often requires skilled technicians who can set up the system, calibrate the machine, and ensure it’s running smoothly. For complex systems, such as Topkey Medical's AVF Needle Assembly Machines, which offer advanced automation and integrated features, professional installation is essential for achieving optimal performance. The technician’s fees, along with any necessary calibration and testing, can add to the overall cost of the machine.

● Setup Fees: Costs for installing the machine and testing its functionality.

● Calibration: Ensuring the machine is adjusted for maximum precision and productivity.

Once installed, training costs for your operators should be considered. For high-tech systems, operators need thorough training to ensure they can run the machine efficiently. Additionally, post-purchase technical support is essential to keep the system running smoothly, addressing any issues that may arise during operation.

Service | Estimated Cost | Description |

Installation | Varies by system complexity | Setup, calibration, and machine testing |

Training | Included or Additional | Operator training to ensure proper machine use |

Technical Support | Subscription/Annual Fees | Ongoing assistance to maintain machine performance |

The shipping of AVF Needle manufacturing machines involves significant costs due to the size and weight of the equipment. Industrial machines often require special handling during transport, which can increase costs. Additionally, the distance and logistics involved in shipping these heavy machines from the manufacturer to your facility can add up quickly.

● Special Handling: High-tech machines need to be transported with extra care.

● Shipping Fees: Based on machine size, weight, and distance.

Shipping high-value equipment like AVF Needle machines also requires appropriate insurance. Insuring the machine during transit protects against potential damage or loss. Delivery fees are another important consideration, especially for international shipping.

Shipping Consideration | Cost Implication | Details |

Shipping & Handling | Varies by destination | Special care and transport for large machines |

Insurance | Typically 1–3% of machine cost | Protects against damage or loss during transit |

Delivery Fees | Based on distance | Additional charges for delivery to your facility |

Regular maintenance is essential to ensure the AVF Needle machine operates efficiently over time. Maintenance costs may include routine servicing, part replacements, and system checks. Topkey Medical recommends regular servicing to prevent downtime and extend the life of the machine.

● Routine Servicing: Scheduled maintenance to ensure optimal machine function.

● Unscheduled Repairs: Additional costs if unexpected issues arise.

Spare parts for high-precision machines, such as those used for AVF Needle manufacturing, can be costly. Ensure that the parts are readily available, as delays in obtaining replacements can result in significant downtime. The cost of spare parts should also be factored into the overall ownership cost.

Maintenance Type | Cost Implication | Details |

Routine Maintenance | Fixed or periodic costs | Servicing and parts replacement as part of regular care |

Spare Parts | Varies by machine | Availability of parts for machine repairs |

Unscheduled Repairs | Variable | Extra costs if issues arise outside scheduled maintenance |

When purchasing an AV Fistula Needle machine, it's crucial to first calculate your expected daily or monthly production. The machine you choose must match these requirements to ensure optimal efficiency without overspending on unnecessary capacity. If you need a machine that can handle 2,000–4,000 units per day, make sure the machine can support that throughput to avoid underperformance or delays.

● Production Volume: Consider how many needles you plan to produce daily, weekly, and monthly.

● Machine Throughput: Choose a machine that can handle your output without going beyond your needs.

As your production needs evolve, your equipment should have the capacity to scale. Machines like Topkey Medical’s AVF Needle Assembly Machines are designed to offer modular upgrades. This ensures you don’t need to invest in an entirely new machine as your business grows, providing a cost-effective way to expand production capacity.

Consideration | Details |

Current Production Needs | Estimate daily/monthly units needed |

Scalability | Ensure the machine can grow with your business |

Throughput Capacity | Match the machine’s output capacity to your needs |

One of the key decisions when choosing a machine is whether to invest in fully automated systems like those offered by Topkey Medical. These machines come at a higher price, but their benefits are numerous: increased speed, reduced labor costs, and improved consistency. If your production volume justifies the investment, fully automated systems provide long-term savings through efficient operation and fewer manual interventions.

● Higher Cost, Higher Efficiency: Fully automated systems save labor costs and increase throughput.

● Consider Production Scale: If your current needs are modest, a semi-automatic machine might still suffice.

While semi-automatic machines are more affordable upfront, they come with the trade-off of requiring more labor for tasks like loading components and conducting inspections. These machines may still be suitable for businesses with lower production volumes or those just starting in needle manufacturing, but you’ll need to consider how much labor will be required to maintain an efficient process.

Automation Level | Cost Range | Advantages | Disadvantages |

Fully Automated | Higher (US$160,000–US$220,000) | Increased speed, reduced labor | Higher initial investment |

Semi-Automatic | Lower (US$15,000–US$60,000) | Lower cost, more manual control | Requires more labor and supervision |

In the production of AVF Needles, maintaining high quality is critical, especially considering that these needles are used in medical procedures like hemodialysis. Any defects or inconsistencies in needle assembly can have serious consequences, potentially affecting patient safety. This is why it’s essential to choose machines that incorporate advanced vision systems and automated quality control mechanisms. These systems can detect defects in real-time, ensuring that only high-quality Arteriovenous Fistula Needles reach the end of the production line.

Machines equipped with vision inspection systems and automated control features not only improve safety but also help reduce production costs by minimizing waste and rework. Topkey Medical’s AVF Needle Assembly Machines, for example, integrate these high-tech features to ensure precision and compliance with medical standards.

Quality Control Feature | Function |

Vision Inspection Systems | Detects defects in needle assembly in real-time |

Automated Control Systems | Ensures consistent quality throughout production |

Precision Calibration | Maintains needle accuracy and reliability |

Investing in high-quality quality control systems is essential to maintaining consistency in AVF Needle production. These systems should cover every stage of manufacturing, from needle assembly to final inspection. By utilizing systems that ensure precise assembly and immediate defect detection, manufacturers can avoid costly mistakes and maintain consistent output quality.

● Integrated Vision Systems: Essential for detecting even minor defects during production.

● Automated Quality Control: Reduces human error and increases reliability in high-volume production.

● Precision Calibration: Ensures each needle meets medical standards for safety and effectiveness.

When purchasing an AV Fistula Needle machine, it’s crucial to review the support and service packages offered by the supplier. Look for comprehensive packages that include installation, operator training, and ongoing technical support. These services ensure that the machine operates at peak efficiency and helps prevent downtime during production.

Topkey Medical offers robust support services, which include thorough installation procedures, hands-on training, and continuous technical assistance to ensure smooth machine operation. It’s essential to have these services included as part of your investment to maximize the machine’s lifespan and performance.

Service Package | Included Features |

Installation | Setup, calibration, and testing of the machine |

Training | Operator training and machine operation guidance |

Technical Support | Ongoing assistance and troubleshooting |

Long-term service contracts are another consideration to reduce operational costs over the life of the machine. These contracts typically include regular maintenance, repairs, and access to spare parts. By securing a long-term service agreement, you can ensure that your AV Fistula Needle machine remains in good working condition and avoid unexpected repair expenses that could disrupt production.

● Routine Maintenance: Regular inspections and servicing to keep the machine in optimal condition.

● Spare Parts and Repairs: Access to replacement parts and support for unexpected breakdowns.

● Cost Efficiency: Long-term service contracts reduce the likelihood of costly repairs and downtime.

Service Type | Benefits |

Routine Maintenance | Keeps the machine running smoothly |

Spare Parts and Repairs | Reduces downtime and maintenance costs |

Long-Term Agreements | Provides peace of mind and cost savings |

In this guide, we explored the key factors that influence the cost of AVF Needle machines, from automation levels to quality control features. Topkey Medical offers high-quality machines tailored to your production needs, helping businesses achieve efficiency, precision, and long-term savings.

A: An AVF Needle machine is designed for automating the assembly of Arteriovenous Fistula Needles, used in hemodialysis. It ensures consistent quality and high precision in needle production.

A: The AVF Needle Assembly machine enhances efficiency by automating needle assembly, reducing labor costs, and increasing production speed while maintaining high-quality standards.

A: The cost depends on automation level, production capacity, and quality control features. Machines with higher throughput and integrated inspection systems tend to be more expensive.

A: Consider your production volume, required AVF Needle sizes, and the level of automation that suits your business needs for efficient and cost-effective manufacturing.

A: Quality control ensures the AVF Needle meets medical standards, reducing defects and ensuring patient safety. Automated inspection systems help maintain consistent quality during production.